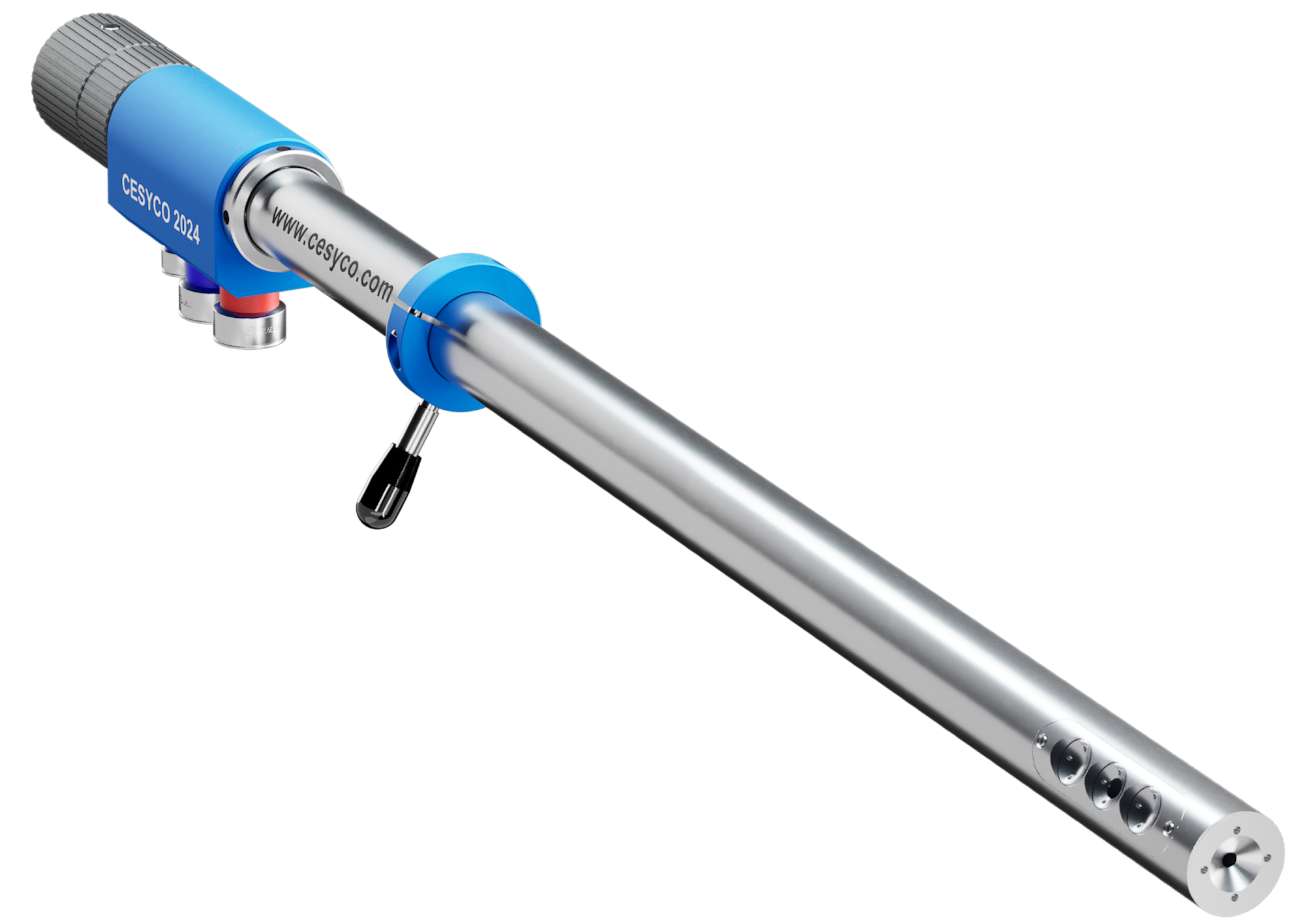

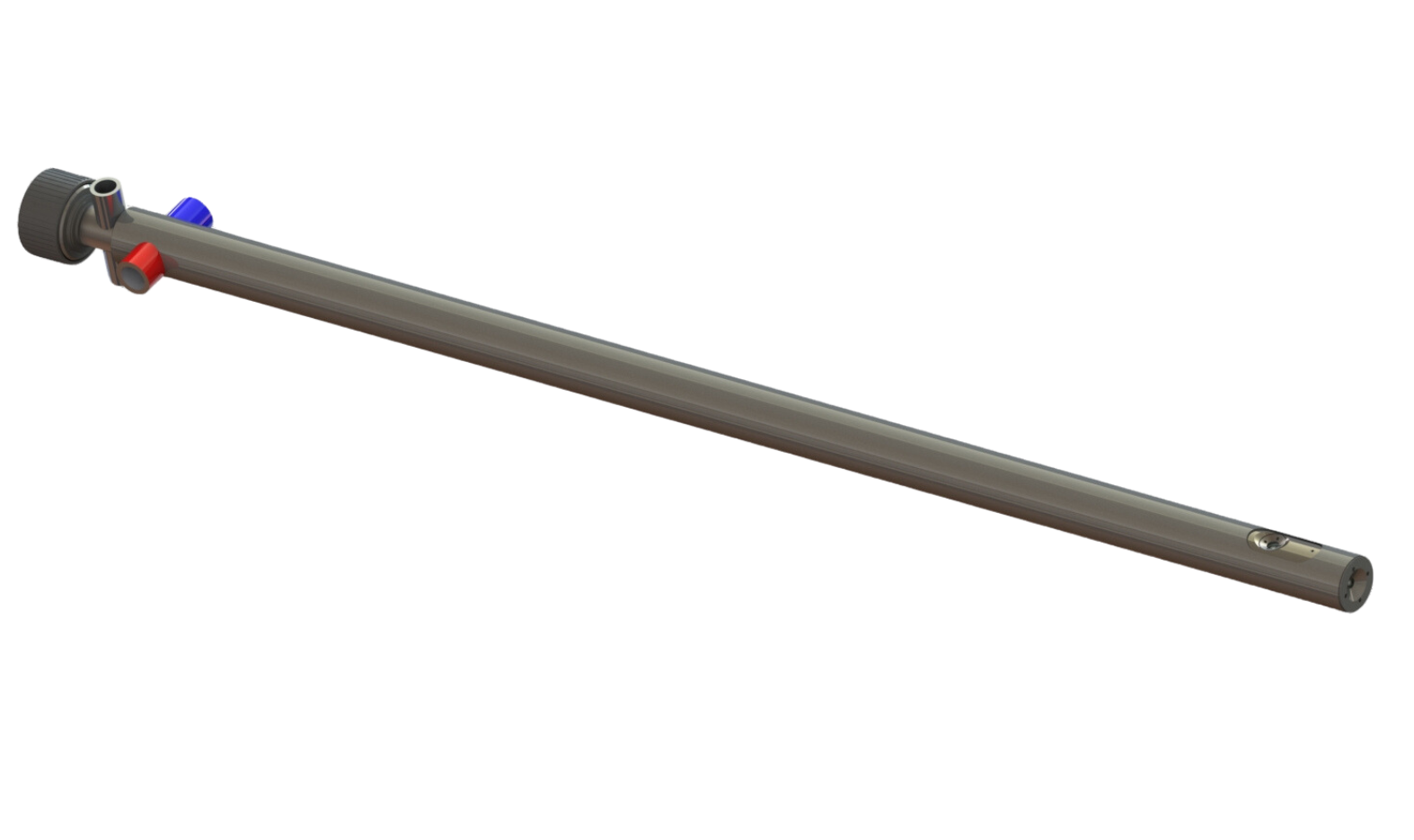

La gaine en inox est refroidie par l'eau et l'air afin de :

- répartir la température sur toute la gaine

- supprimer les points chauds responsables de rupture de soudure

- augmenter la durée de vie de la gaine

Grâce à une clé de rotation, vous avez la possibilité de faire tourner la gaine sur elle-même, offrant une configuration de vision complète.

- Double vision : voyez les côtés et l'avant du four en même temps.

- Plusieurs angles disponibles : têtes de caméra orientées à 20°, 45° et 65°.

- Eclairage par Led

La gaine en inox est refroidie par l'eau et protège de la chaleur. Cette conception permet :

- la répartition homogène de la température sur toute la gaine

- la suppression des points chauds (responsables de rupture de soudure)

- l'augmentation de la durée de vie de la gaine

- l'utilisation à des températures très élevées

- Double vision : voyez les côtés et l'avant du four en même temps.

- Plusieurs angles disponibles : têtes de caméra orientées à 20°, 45° et 65°.

- Eclairage par Led

To summarize, the key factors to consider when selecting a fixed or portable endoscope are compiled in the comparison table below:

Comparison Criteria |

Portable endoscope |

Fixed endoscope |

|---|---|---|

| Frequency of Use | Occasional / One-time use | Continue |

| Mobility | High | None |

| Operating Temperature | Moderate / high for short durations | Very high, continuous exposure |

| Human Intervention Risks | Present | Limited (remote operation) |

| Diagnostic ToolPreventive Maintenance | Diagnostic tool | Monitoring tool |

Please note: Our endoscopes are custom-designed based on your technical constraints and inspection objectives. This comparison provides you with an initial guidance, but to precisely define the type of endoscope suitable for your environment, our technical teams are at your disposal. Don’t hesitate to contact them: They will be able to answer your questions and guide you towards the most relevant solution.

Conclusion

The choice between a fixed or portable endoscope primarily depends on your usage, the frequency of inspections, and the specific constraints of your industrial environment. A portable model will be ideal for occasional interventions and mobility, while a fixed model will ensure continuous and secure monitoring of critical high-temperature areas.

At Cesyco, we design each endoscope taking into account real-world conditions: extreme environments, accessibility, performance requirements, and durability.

👉 Need help choosing between a fixed or portable endoscope?

Our experts will assist you in analyzing your needs to offer a solution perfectly adapted to your facilities.