Articles & News

Our Articles

Welcome to our selection of Articles on High-Temperature Inspections.

In this section, CESYCO shares its expertise on industrial endoscopy, its practical applications and the challenges of inspections in extreme environments.

Whether you’re a technician, maintenance manager or simply curious to understand the technologies used in industrial furnaces or thermal power plants, you’ll find useful resources here.

Our content covers everything from technical advice and feedback from the field to news on industrial endoscopy.

High-temperature inspections require reliable equipment and real expertise. This is what we propose to explore, article after article.

The bases of inspection :

What is Industrial Endoscopy and why is it Essential?

Industrial endoscopy uses optical devices to inspect inaccessible areas, adapted to extreme conditions. It prevents breakdowns, improves safety, optimizes maintenance, and increases operational efficiency. Thanks to solutions like CESYCO, companies can meet the challenges of demanding industrial environments.

The importance of hot inspections in high-risk industries

In high-risk industries such as steel, glass, and waste incineration, hot inspections play a vital role in ensuring safety, reliability, and operational continuity. But why are they so crucial? Here’s an overview of their importance.

5 things you need to know about inspections in high-temperature environments

High-temperature inspections in furnaces or boilers require specially adapted tools. They enhance safety, facilitate predictive maintenance and improve visibility in sectors such as glassmaking, steelmaking, energy and cement.

How do you choose the right endoscope for your industry?

Industrial endoscopy makes it possible to inspect inaccessible areas under extreme conditions. Whether fixed or portable, each model meets a specific need depending on the sector. Hot inspections, carried out by CESYCO, ensure both safety and performance.

Applications and case studies :

Industrial Endoscopy: a Key Solution for Metallurgical Furnace Inspection

The inspection of metallurgical equipment such as blast furnaces, coke ovens, and tunnel furnaces is crucial to ensure safety and production quality. The use of industrial endoscopes enables continuous monitoring, promotes proactive maintenance, and prevents breakdowns, thus improving operational efficiency.

Spotlight on Urban Waste Incinerator Inspection

Urban waste incinerators operate continuously under extreme conditions. To avoid unexpected shutdowns and optimize their performance, regular inspection of critical areas is essential. Discover how industrial endoscopy allows for effective action without interrupting activity, even in the most hostile environments.

Hot repairs in industrial furnaces: the essential tools

In glassmaking, steelmaking, or cement plants, hot repairs make it possible to maintain production without shutdowns. CESYCO endoscopes ensure safe and precise inspections, reducing downtime and improving performance.

High-temperature inspection: key applications in thermal power plants

Thermal power plants, powered by various sources, require continuous monitoring to ensure efficiency. High-temperature inspections are critical to prevent failures and optimize safety. CESYCO’s endoscopy solutions make it possible to diagnose and monitor equipment condition without interrupting production, thereby reducing costs.

How industrial endoscopy optimizes production in the glass industry

Industrial endoscopy is essential in the glass industry, where production conditions are critical. This technology enables continuous monitoring, failure prevention, enhanced safety and process optimization, contributing to the sustainability and competitiveness of companies while guaranteeing quality performance.

Technologies and innovations :

Fixed or portable endoscope: which is right for you?

Fixed or Portable endoscope: how to make the right choice? This article helps you identify the equipment best suited to your industrial inspections.

Industrial endoscopic vision: understanding angles, fields, directions and lighting

Angles, fields of view, directions, and lighting are essential in industrial inspection. CESYCO technologies adapt to every environment to provide a clear and accurate image, even in hard-to-reach areas.

2000°C resistance: the challenge for industrial endoscopes

High-temperature industrial environments demand endoscopes capable of withstanding extreme conditions. Materials such as stainless steel, Hastelloy and Arcap are essential to guarantee durability and performance. Air- and water-cooling systems, combined with a triple-envelope sheath, ensure effective protection against heat and corrosion.

Service and maintenance :

Why sending your endoscope back to the workshop can save its life

Even well-maintained industrial endoscopes deserve a thorough check-up. Find out why a return to the workshop can save it from a fatal breakdown.

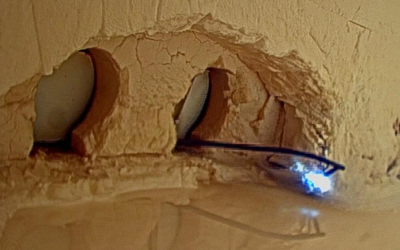

What to do if the image becomes blurred? Signs of a malfunctioning endoscope

A blurred image can be the symptom of simple clogging… or the sign of a damaged endoscope. Find out how to identify the cause and take effective action.

The right gestures to prolong the life of your endoscope

In extreme environments, a high-temperature endoscope must be well maintained. Learn the proper handling, cleaning, and inspection procedures to extend its service life and preserve image quality during your inspections.

Our News

Keep up to date with CESYCO events, innovations, partnerships and internal developments. Here, we share the highlights of our corporate life, as well as important announcements.

Stay connected to our industrial world, and discover what goes on behind the scenes in high-temperature endoscopy.

Summer closure: August 9 to 24, 2025

The CESYCO team is taking a summer break! Our offices and workshops will be closed from Saturday August 9 to Sunday August 24 inclusive. We’ll be back in business on Monday August 25. Have a great summer!

FAQ

Do you have a quick question about the use of an endoscope, its limits at high temperatures, or good maintenance practices?

This FAQ contains answers to the most frequently asked questions by our customers, straight from the field. Each answer is concise, clear, and sometimes accompanied by a link to a more detailed article if you wish to go further.

Our aim: to save you time and make your work more reliable, even in the most extreme environments.

What's the difference between an industrial endoscope and a borescope?

A borescope is a standard and often flexible inspection tool, used to observe hard-to-reach areas at ambient temperature. An industrial endoscope, like those designed by CESYCO, is rigid and specifically developed to withstand extreme conditions (up to 2000°C), offering reliable vision in constrained environments thanks to integrated cooling and custom-made components.

Can you inspect molten glass?

Yes, with a fixed power-cooling endoscope, used in basin furnaces for example. In this case, the burners, refractory walls or bath surface are inspected.

What's the difference between destructive and non-destructive testing (NDT)?

Non-destructive testing (such as endoscopy) enables us to check the internal condition of a piece of equipment without damaging or stopping it. Destructive testing involves taking a sample or performing a test that damages the part.

What is the maximum length of a rigid endoscope?

At CESYCO, some rigid models can reach 7 meters, but maneuverability and optical clarity diminish with length.

The endoscope overheated during inspection. Is it ruined?

Not necessarily. If the cooling system has temporarily failed, a workshop test will enable you to assess the damage. If in doubt, it’s best not to use the unit again.

Can the endoscope be inserted into a very narrow opening?

CESYCO’s smallest diameters are up to 40 mm. In order to withstand extreme temperatures, we need a high-performance cooling system that guarantees impeccable image quality.

Can an endoscope be used on a dusty or corrosive site?

Yes, as long as you choose the right model (with air supply, protective sheaths, protected optics). In the event of heavy corrosion, rapid cleaning is essential.

Can an endoscope be used after a local repair (ceramic welding, gunning, etc.)?

Yes, and it’s even recommended to validate the effectiveness of the repair and identify areas of residual risk.