An industrial endoscope is a precision piece of equipment, designed to withstand extreme conditions: high temperatures, dusty atmospheres, corrosive environments. However, despite its robustness, it is not indestructible.

Even with proper cleaning after every intervention, wear and tear is inevitable. Malfunctions can appear without warning, and an external visual inspection is not always enough to detect the warning signs.

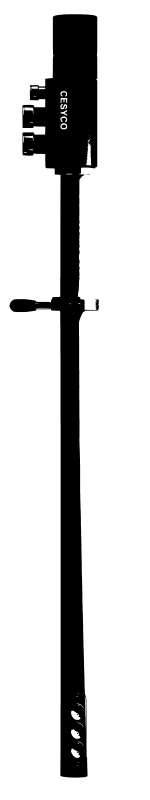

That‘s where the Cesyco workshop comes in: a punctual return not only anticipates breakdowns, but also preserves optical performance and safety of use. In short, it’s a guarantee of long-term reliability.

When should you consider returning to the workshop?

Certain symptoms should immediately alert the user. If you notice any of the following signs, we strongly recommend that you have your equipment serviced:

-

The image remains blurred despite careful cleaning: this may indicate an optical fault or an internal deposit that is not accessible.

-

Soot, burn marks or oxidation visible on the sheath or around the lens.

-

Abnormal ingress of water, air or particles: often linked to loss of tightness due to worn seals or poor connections.

-

Visible wear, thermal shock or suspicion of microcracking after work in a particularly aggressive environment.

In all these cases, a workshop inspection enables us to diagnose the exact cause of the problem and restore the endoscope to optimum working order.

What actually happens in the workshop?

A workshop visit is more than a simple overhaul: it’s a targeted refurbishment, adapted to the equipment’s actual operating conditions.

Here are the main steps carried out by our specialized technicians:

- Complete visual and optical diagnostics: check lens, sheath, connectors and housing.

- Thorough internal cleaning, especially of optics, with re-polishing if necessary.

- Check electronics (for digital models): test camera, video signals, lighting, buttons and connectors.

- Checking and cleaning cooling circuits, whether air- or water-cooled. These channels can be blocked by invisible deposits.

- Replacement of worn or damaged parts: sheaths, seals, portholes, lenses, cables…

- Final validation with performance tests, to ensure that the endoscope is ready to return to site without risk.

4. Why is maintenance essential?

A return to the workshop is much more than a repair: it’s a preventive approach, essential to avoid unpleasant surprises in the field.

Here’s what this revision does for you:

-

Detection of micro-defects invisible to the naked eye, before they become serious.

-

Optimum long-term performance, even in harsh environments.

-

Reduced risk of inspection stoppages in the middle of a mission, with equipment that keeps its promises.

-

Protection against progressive damage: heat, dust, impact, corrosion…

-

Enhanced safety: a reliable endoscope also protects the technicians who use it.

💡 Cesyco recommendation: for optics, we recommend a return to the workshop once a year, even without visible symptoms, as part of preventive maintenance.