Products

Cesyco offers custom industrial endoscopy solutions for your high-temperature inspections. Discover our range of fixed and portable endoscopes, designed to provide high-quality images, even in the most demanding industrial environments. Robustness, precision, and reliability at the service of your business.

Endoscopes

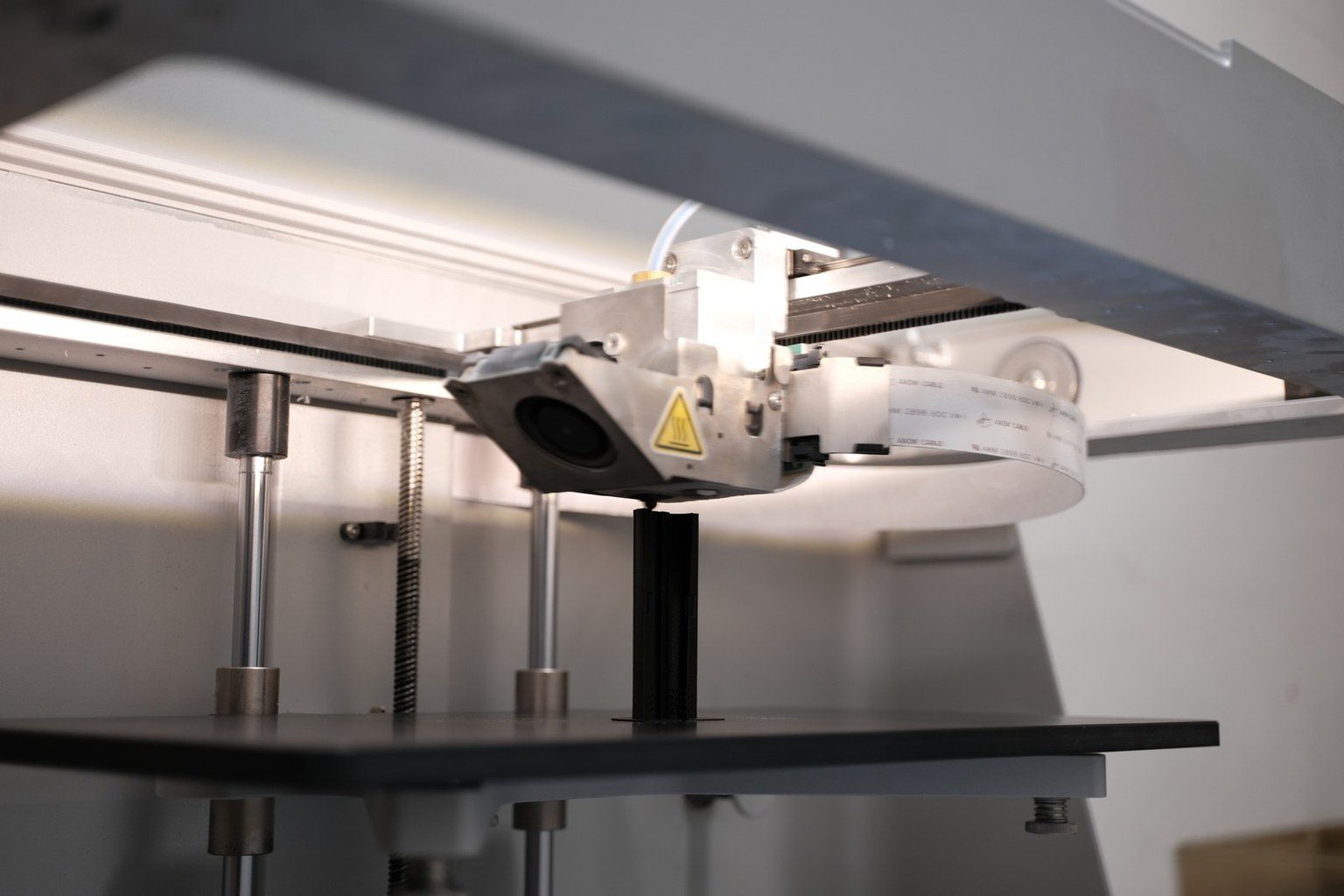

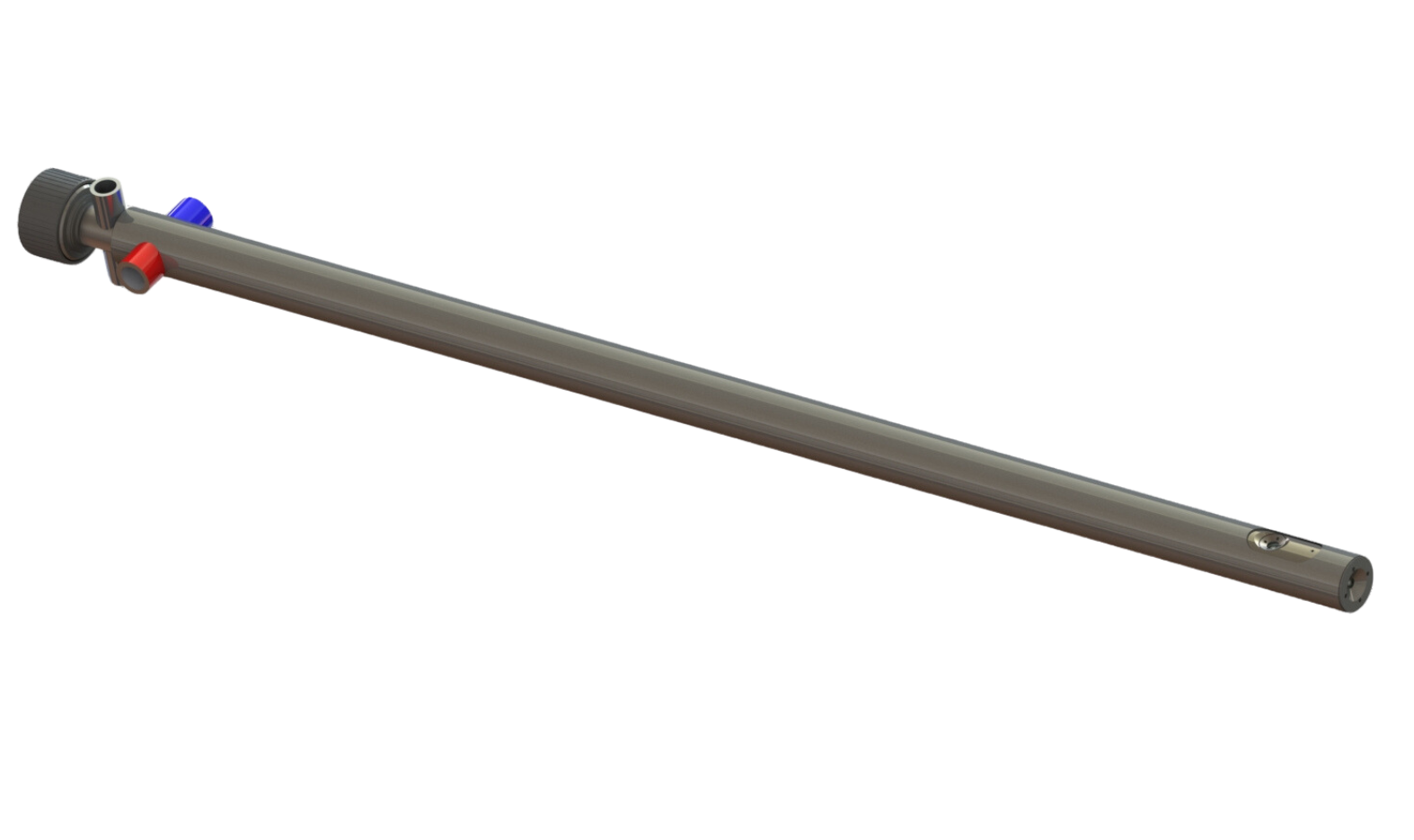

The stainless steel sheath is cooled by water and air in order to:

- distribute the temperature throughout the sheath

- eliminate hot spots that cause weld breakage

- increase the service life of the sheath

Thanks to a rotation key, you can rotate the sleeve on itself, offering a complete viewing configuration.

- Dual vision: see the sides and front of the oven at the same time.

- Multiple angles available: camera heads oriented at 20°, 45°, and 65°.

- LED lighting

The stainless steel sheath is cooled by water and protects against heat. This design allows for:

- even temperature distribution throughout the sheath

- elimination of hot spots (responsible for weld breakage)

- increased sheath service life

use at very high temperatures

- Dual vision: see the sides and front of the oven at the same time.

- Multiple angles available: camera heads oriented at 20°, 45°, and 65°.

- LED lighting

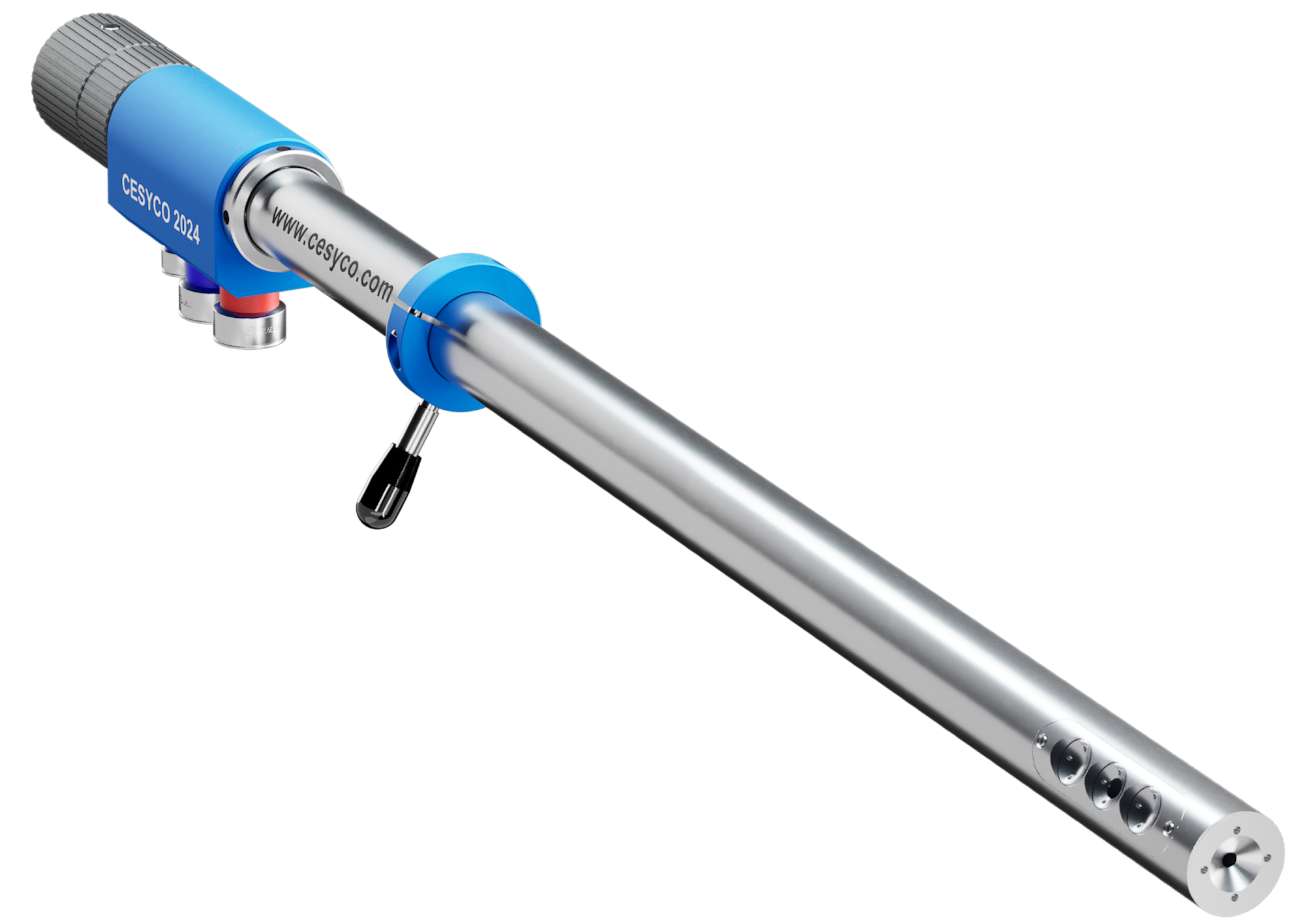

Discover the HTN40 in Video: a Portable Endoscope Designed for Extreme Environments

This 3D video takes you inside the HTN40 portable endoscope, a device developed for industrial inspection in high temperatures, in direct contact with operating furnaces.

You will discover the various components that make up this robust and compact system, designed to withstand the most severe thermal conditions. Thanks to its optimized design, the HTN40 captures clear, usable images in complex industrial environments, while facilitating on-site integration.

The HTN40 portable endoscope is an ideal solution for quick, reliable, and non-intrusive visual inspections in sectors such as glassmaking, steelmaking, incineration, or the refractory materials industry.

Technology

Equipment

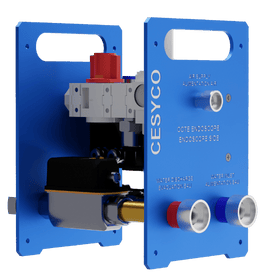

Safety Station

Highly recommend

Immediate detection of anomalies thanks to an audible and visual alarm in the event of a fault (insufficient air pressure, inadequate flow rate, or water overheating).

Control Box

Needed for digital endoscope

Efficient data transmission for high-quality real-time inspections. Allows you to monitor the photo/video signal and triggers an alarm in the event of an anomaly.

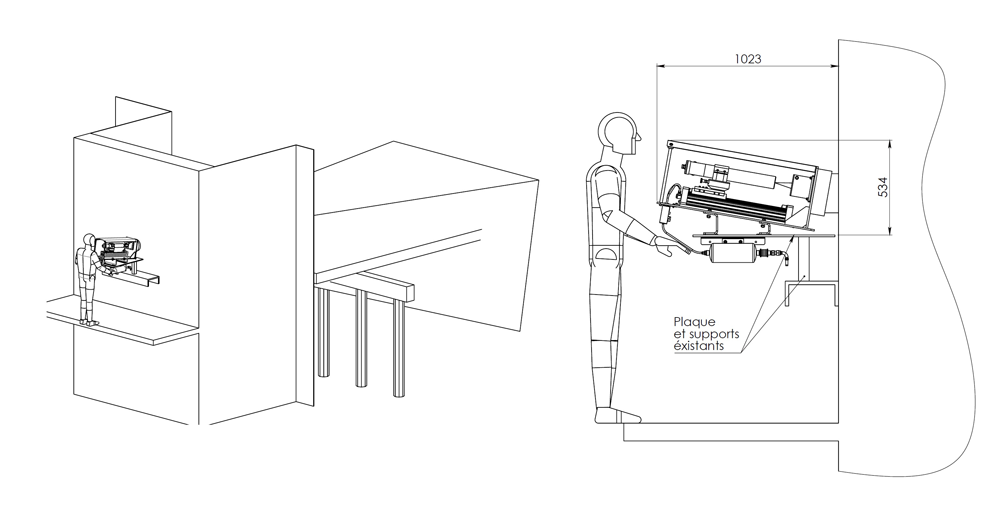

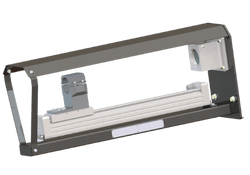

Extractor Bench

Guarantees safety

The extractor bench facilitates the insertion and removal of the endoscope while ensuring its automatic extraction in the event of cooling failure.

Cabinet

Manage the bench

The alarm signals any anomalies in air pressure, flow rate, or excessive water temperature. The box powers the endoscope and provides the link to the control room.

Service

In the most demanding industrial environments, every detail matters. That’s why CESYCO offers you its expertise and high-performance equipment to conduct visual inspections at high temperatures, directly on your site.

Thanks to our specialized endoscopes, we capture high-quality images from inside your facilities, allowing you to monitor wear, detect anomalies, and optimize maintenance, all without production stoppage.

Contact

We analyze your specific needs and propose a tailor-made solution. This stage includes the precise targeting of your requirements and the preparation of a customized quotation.

Intervention

Our technicians come directly to your site, equipped with state-of-the-art equipment. They carry out inspections in complete safety, even in the most demanding environments.

Image delivery

At the end of the inspection, we provide you with the high-quality images captured during the inspection. These visual aids, in photo or video format, are ready to be used according to your needs.

- Check the internal wear condition of an operating furnace.

- Anticipate and plan maintenance operations.

- Monitor a hot process in real-time.

- Detect any malfunction without stopping production.

Simulation & 3D Printing

At CESYCO, we use 3D printing to speed up the design phase and push back the boundaries of customization. This process enables us to quickly test shapes, validate concepts and create parts perfectly adapted to the specific constraints of each customer.

In addition, our design office carries out precise 3D simulations of the customer’s environment. This key step guarantees optimal placement of the endoscope in the oven, and ensures the best possible quality of vision. With this approach, we secure the integration of the equipment and offer our customers a faithful projection of the solution before its implementation.