HTN40F

Digital fixed multivision endoscope- Advanced Cooling System

- 360° Rotation

- Axial and/or lateral view

- Adaptable fields of view

- LED lighting

Safe, continuous monitoring with our high-temperature fixed endoscopes

Fixed endoscopes have been specially developed for continuous industrial inspection in very high-temperature environments, without stopping production. Installed directly on the wall of the furnace or equipment to be inspected, they provide a permanent, stable view of critical areas, even in extreme conditions. Suitable for glass furnaces, coke ovens, incinerators and other thermal installations, these devices provide precise, reliable monitoring of flames, refractory walls, burners or material flows.

Compatible with the most severe conditions, our fixed endoscopy systems incorporate high-performance cooling technologies calibrated to withstand thermal shocks over the long term. Custom installation and low maintenance make them ideal for enhancing safety, anticipating defects and optimizing your inspection operations in hot environments.

Digital

HTN40F

Temperature up to 1,600 °C

portable

variation

The HTN40 is equipped with a Full HD camera and a cooling sheath, making it suitable for high-temperature inspections up to 1,600 °C.

It provides both axial and lateral views, with LED lighting for low-light environments.

The stainless steel sheath is available in various lengths to suit different industrial settings.

Digital fixed multivision endoscope

HTN70

Temperature up to 2,000°C

The HTN-70 videoscope with IP video module is primarily designed for 24/7 production monitoring in large high-temperature furnaces, enabling real-time tracking of the manufacturing process.

Continuous observation is ensured by the integrated Full HD digital video module, allowing image visualization from the control room.

The HTN-70 videoscope is available in various lengths, viewing angles, and fields of view.

Fixed endoscope for extreme conditions

LEDs

HTN78

Temperature up to 1,400 °C

Water-proof

variation

Thanks to its axial (0°) LED lighting, it provides optimal visibility and delivers high-definition images even in the most demanding conditions.

Its IP video module enables real-time transmission for accurate and continuous monitoring of industrial processes.

Equipped with a triple-layer sheath and an advanced cooling system (air and water), the HTN78 combines robustness, safety, and performance for reliable 24/7 monitoring.

High-temperature imaging in low-light conditions

Equipment

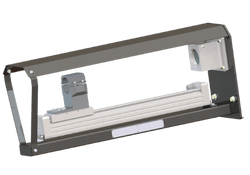

Safety Station

Highly recommend

Immediate detection of anomalies thanks to an audible and visual alarm in the event of a fault (insufficient air pressure, inadequate flow rate, or water overheating).

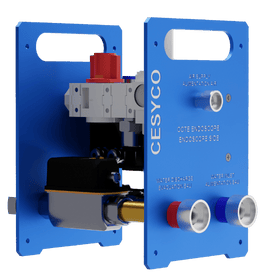

Control Box

Needed for digital endoscope

Efficient data transmission for high-quality real-time inspections. Allows you to monitor the photo/video signal and triggers an alarm in the event of an anomaly.

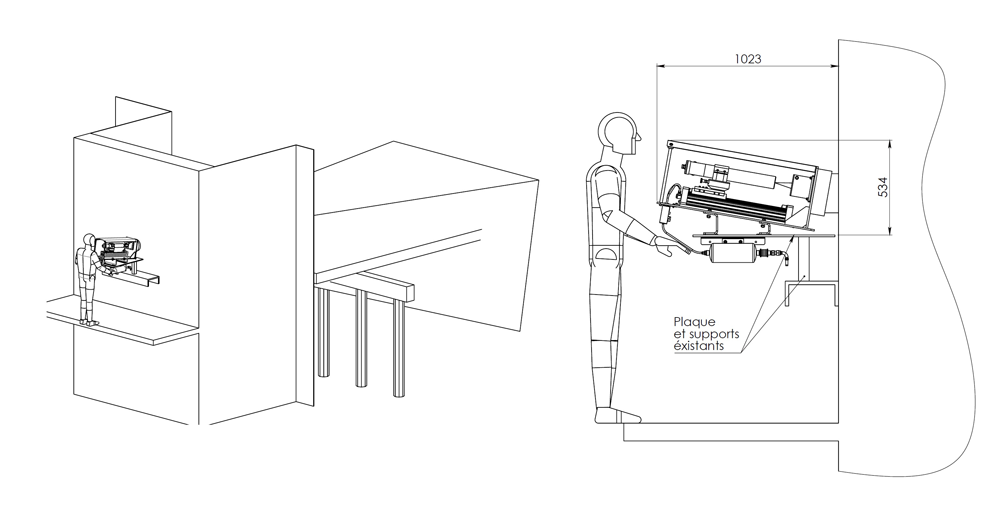

Extractor Bench

Guarantees safety

The extractor bench facilitates the insertion and removal of the endoscope while ensuring its automatic extraction in the event of cooling failure.

Cabinet

Manage the bench

The alarm signals any anomalies in air pressure, flow rate, or excessive water temperature. The box powers the endoscope and provides the link to the control room.

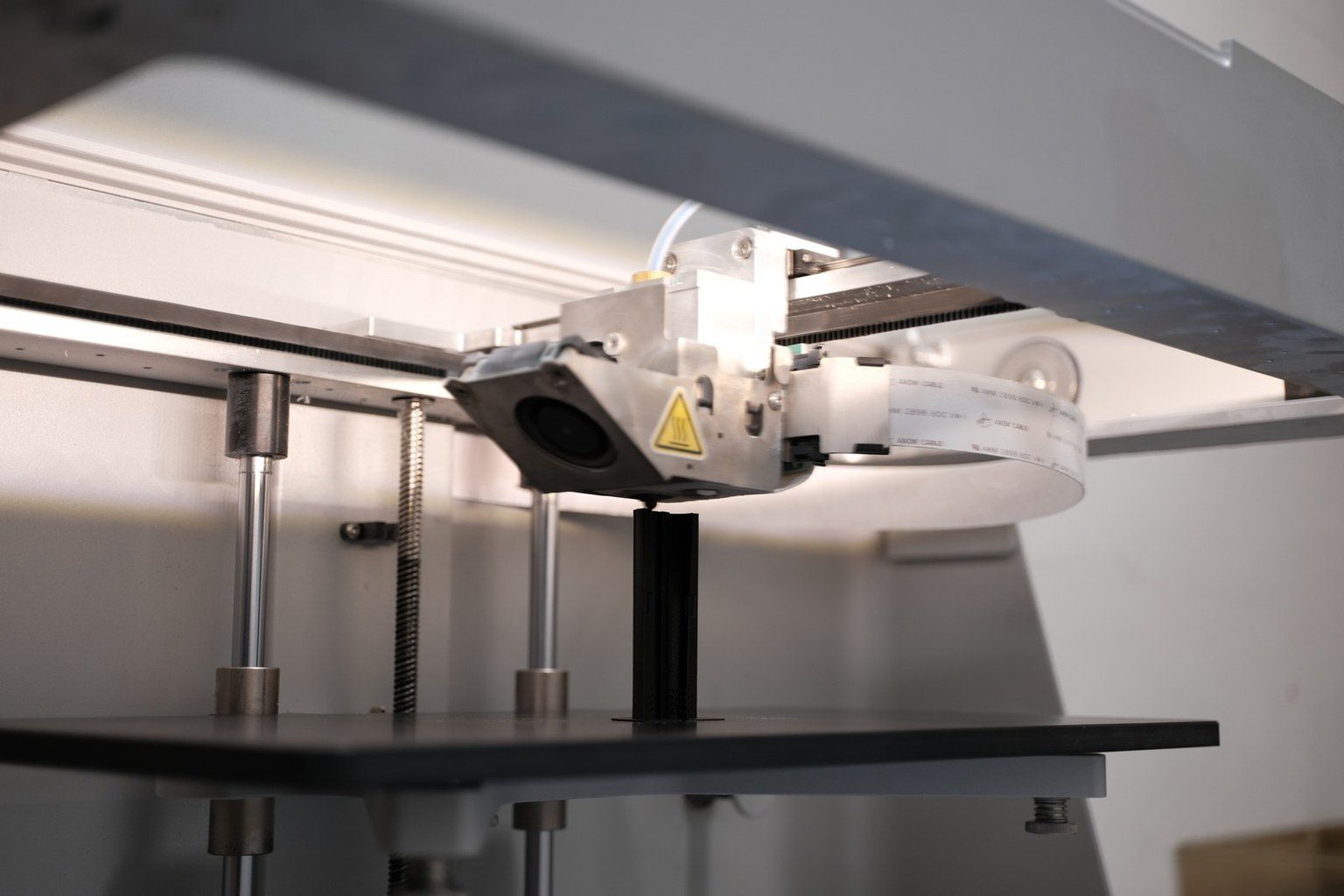

3D Simulation

Our engineering team supports each client throughout the project to ensure the best visual inspection strategy. With a thorough understanding of the industrial environment — whether it’s a furnace, incinerator, boiler, or any other high-temperature equipment — we design fully customized inspection plans. This tailored approach allows us to adapt our industrial endoscopy systems to each specific setup, ensuring optimal access and maximum image quality. Our goal: to deliver reliable inspections, without production shutdowns, even in the most demanding conditions.

Our engineering team also integrates 3D printing into the development process to create technical solutions that perfectly match the constraints of each site. This technology enables us to rapidly produce custom parts—such as adapters, mounts, or protective elements—designed specifically for the client’s environment. Whether it’s a furnace, boiler, or incinerator, we can deliver tailor-made components, even for complex access points or extreme conditions. 3D printing gives us the flexibility to test, refine, and validate solutions before final production, while ensuring high performance, durability, and reliability.